Hot sale black annealed small coil 3.5LBS banding wire for building

Small coil wire also called rebar tie Wire, can be supplied in coiled wire forms for the steel rebar fixing and tying demands in

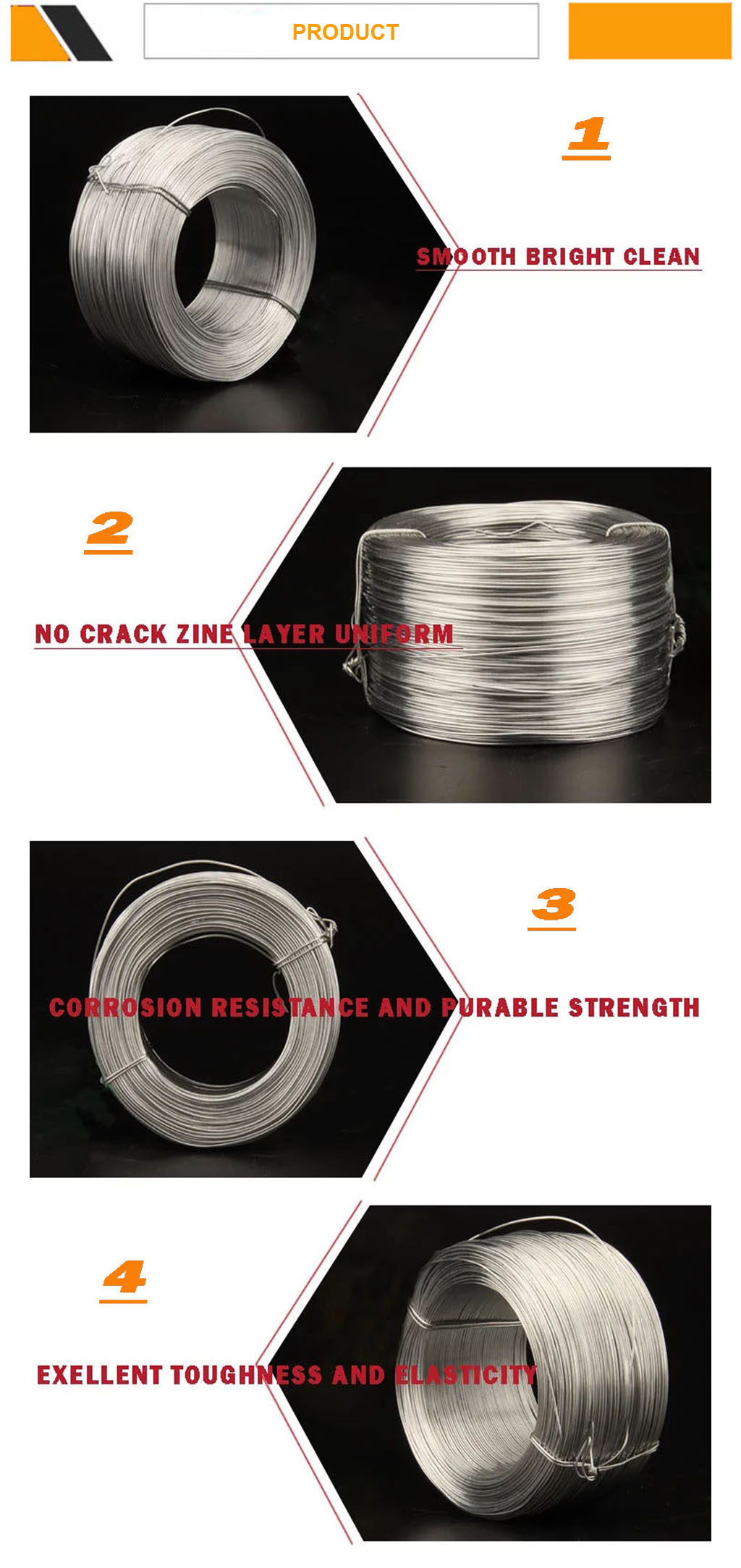

concrete construction. BSmall Coil Wire is typically made from low carbon steel, which provides sufficient strength while remaining pliable enough for manual bending and tying. It is often galvanized to resist corrosion, particularly in environments where the concrete will be exposed to moisture or chemicals.

Application: Mainly used as tie wire rope or in building .wire mesh production and production of civilian industry. soft annealed wire

offers excellent flexibility and softness through the process of free oxygen annealing. we can do it in straight cut wire, U type wire and also according to the special requirements of users.

Advantage Big real factory, we can satisfy you products with good quality, fast delivery and satisfied service. Galvanized wire is made of high-quality low-carbon steel wire rod, which is divided into hot-dip galvanized wire and cold-galvanized wire.

Hot dip galvanizing is dipped into a heated molten zinc solution. The production speed is fast, the consumption of zinc metal is large, and the corrosion resistance is good.

Cold galvanizing (electro galvanizing) is to gradually coat the metal surface with zinc through a unidirectional current in the electroplating tank. The production speed is slow, the coating is uniform, the thickness is thin, the appearance is bright, and the corrosion resistance is poor. Black annealed wire is another cold-processed product of steel wire, and the material used is generally high-quality low-carbon steel or stainless steel.

It has good elasticity and flexibility, and its softness and hardness can be controlled during the annealing process. The wire number is mainly 5#-38# (wire length 0.17-4.5mm), which is softer than ordinary black iron wire, more flexible, uniform in softness and consistent in color.

| Wire Gauge | Diameter(mm) | Tensile Strength(kg/mm2) | Zinc Coating | Coil Weight(kg) |

| 6# | 4.60-4.95 | 40-70 | 30-260 | 300-800 |

| 7# | 4.25-4.60 | 40-70 | 30-260 | 300-800 |

| 8# | 3.90-4.25 | 40-70 | 30-260 | 300-800 |

| 9# | 3.65-3.90 | 40-70 | 30-260 | 300-800 |

| 9.5# | 3.49-3.65 | 40-70 | 30-260 | 300-800 |

| 10# | 3.14-3.32 | 40-70 | 30-260 | 300-800 |

| 10.5# | 3.14-3.32 | 40-70 | 30-260 | 300-800 |

| 11# | 2.96-3.14 | 40-70 | 30-260 | 300-800 |

| 11.5# | 2.84-2.96 | 40-70 | 30-260 | 300-800 |

| 12# | 2.70-2.84 | 40-70 | 30-260 | 300-800 |

| 12.5# | 2.50-2.70 | 40-65 | 30-260 | 300-800 |

| 13# | 2.32-2.50 | 40-70 | 30-260 | 300-800 |

| 13.5# | 2.18-2.32 | 40-70 | 30-260 | 300-800 |

| 14# | 2.03-2.18 | 40-70 | 30-260 | 300-800 |

| 14.5# | 1.90-2.03 | 40-70 | 30-200 | 300-800 |

| 15# | 1.76-1.90 | 40-70 | 30-200 | 300-800 |

| 16# | 1.61-1.70 | 40-60 | 20-60 | 300-800 |

| 16.5# | 1.52-1.61 | 40-60 | 20-60 | 300-800 |

| 17# | 1.43-1.52 | 40-60 | 20-55 | 200-350 |

| 17.5# | 1.30-1.43 | 40-55 | 20-45 | 200-350 |

| 18# | 1.19-1.30 | 40-55 | 20-45 | 25-350 |

| 18.5# | 1.11-1.19 | 40-55 | 20-45 | 25-350 |

| 19# | 1.02-1.11 | 40-55 | 20-45 | 25-350 |

| 19.5# | 0.93-1.02 | 35-55 | 20-45 | 25-350 |

| 20# | 0.84-0.93 | 35-55 | 20-45 | 25-350 |

| 21# | 0.76-0.84 | 35-55 | 20-40 | 25-350 |

| 22# | 0.67-0.76 | 35-55 | 20-40 | 25-350 |

| 23# | 0.62-0.67 | 35-55 | 20-40 | 25-350 |