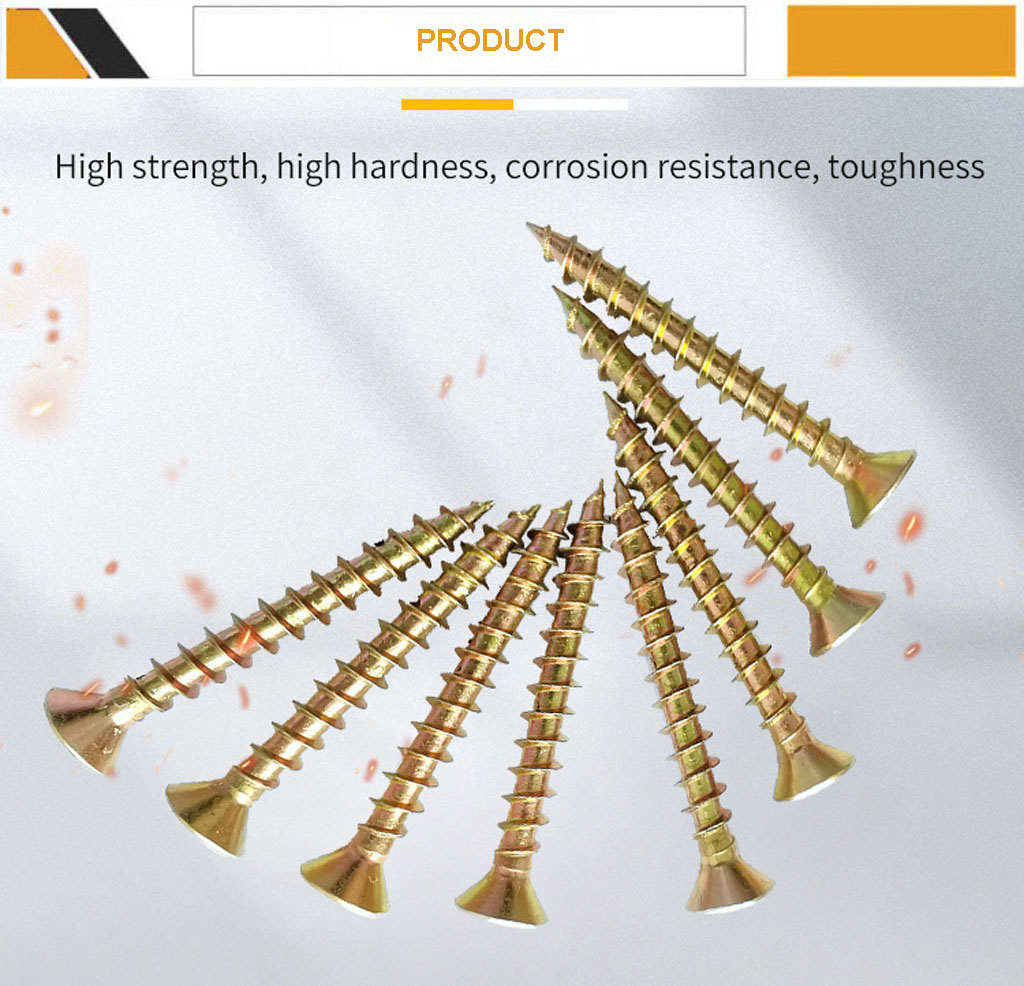

Yellow zinc torx drive double countersunk head wood chipboard screw

Chipboard screws, also named particleboard screws, are self-tapping screws with thin shafts and coarse threads. They are made of carbon steel or stainless steel and then galvanized. Chipboard screws of different lengths can be used in a variety of applications. They are created to fasten low, medium and high density chipboard. Many chipboard screws are self-tapping, so there is no need to drill holes in advance.

The Feature of Chipboard:

1. Easy to screw in

2. High tensile strength

3. Avoid cracking and splitting

4. Deep and sharp thread for cutting through wood cleanly

5. Excellent quality and high-temperature treatment for resistance to snapping

6. Different choices of dimensions and surfaces

7. Construction authorities approved

8. Long service life

China chipboard screw/particle board screw, also named particleboard screws, are self-tapping screws with thin shafts and coarse threads. They are made of carbon steel or stainless steel and then galvanized. Chipboard screws of different lengths can be used in a variety of applications. They are created to fasten low, medium and high density chipboard. Many chipboard screws are self-tapping, so there is no need to drill holes in advance

Our company mainly manufactures pan head, oval had countersunk flat head and double flat head chipboard screws, and customer’s design and requirement are welcome. There are available sizes of the four kinds of chipboard screws in the below table.

Application of Chipboard Screws:

Be widely used in structural steel industry, metal building industry, mechanical equipment industry, automobile industry, etc. Ideal for chipboards and wood, they are often used for cabinetry and for flooring.

Common length (around 4cm) chipboard screws are often used to join chipboard flooring to regular wood joists.

Small chipboard screws (around 1.5cm) can be used to fasten hinges to chipboard cabinetry.

Long (around 13cm) chipboard screws can be used to fasten chipboard to chipboard when making cabinets.

| Dimension | Small packing | Large packing | Weight |

| (mm) | (pcs.) | (pcs.) | (kg/100 pc) |

| 2,5×10 | 1 000 | — | 0,05 |

| 2,5×12 | 1 000 | — | 0,06 |

| 2,5×16 | 1 000 | — | 0,1 |

| 2,5×20 | 1 000 | — | 0,11 |

| 2,5×25 | 1 000 | — | 0,13 |

| 2,5×30 | 1 000 | — | 0,14 |

| 3×10 | 1 000 | — | 0,05 |

| 3×12 | 1 000 | — | 0,06 |

| 3×16 | 1 000 | 45 000 | 0,06 |

| 3×20 | 1 000 | 27 000 | 0,07 |

| 3×25 | 1 000 | 17 000 | 0,08 |

| 3×30 | 1 000 | 17 000 | 0,1 |

| 3×35 | 1 000 | 17 000 | 0,11 |

| 3×40 | 1 000 | 12 000 | 0,13 |

| 3×45 | 1 000 | 10 000 | 0,14 |

| 3×50 | 1 000 | 9 000 | 0,14 |

| 3,5×16 | 1 000 | 27 000 | 0,07 |

| 3,5×20 | 1 000 | 18 000 | 0,09 |

| 3,5×25 | 1 000 | 17 000 | 0,11 |

| 3,5×30 | 1 000 | 14 000 | 0,12 |

| 3,5×35 | 1 000 | 14 000 | 0,14 |

| 3,5×40 | 1 000 | 12 000 | 0,16 |

| 3,5×45 | 1 000 | 9 000 | 0,18 |

| 3,5×50 | 1 000 | 9 000 | 0,2 |

| 3,5×55 | 1 000 | 6 000 | 0,21 |

| 3,5×60 | 1 000 | 6 000 | 0,22 |

| 4×12 | 500 | — | 0,09 |

| 4×16 | 1 000 | 25 000 | 0,1 |

| 4×20 | 1 000 | 20 000 | 0,12 |

| 4×25 | 1 000 | 14 000 | 0,15 |

| 4×30 | 1 000 | 12 000 | 0,17 |

| 4×35 | 500 | 8 500 | 0,19 |

| 4×40 | 500 | 7 000 | 0,21 |

| 4×45 | 500 | 7 000 | 0,23 |

| 4×50 | 500 | 6 000 | 0,26 |

| 4×55 | 500 | 5 000 | 0,29 |

| 4×60 | 500 | 4 500 | 0,32 |

| 4×70 | 250 | 3 500 | 0,37 |

| 4×80 | 250 | 3 500 | 0,42 |

| 4,5×16 | 1 000 | 18 000 | 0,12 |

| 4,5×20 | 1 000 | 14 000 | 0,13 |

| 4,5×25 | 1 000 | 14 000 | 0,17 |

| 4,5×30 | 1 000 | 12 000 | 0,21 |

| 4,5×35 | 1 000 | 9 000 | 0,25 |

| 4,5×40 | 500 | 7 000 | 0,28 |

| 4,5×45 | 500 | 6 000 | 0,31 |

| 4,5×50 | 500 | 5 000 | 0,35 |

| 4,5×55 | 500 | 5 000 | 0,39 |

| 4,5×60 | 500 | 4 500 | 0,44 |

| 4,5×70 | 250 | 3 500 | 0,48 |

| 4,5×80 | 250 | 3 500 | 0,53 |

| 5×16 | 500 | — | 0,172 |

| 5×20 | 1 000 | 12 000 | 0,22 |

| 5×25 | 1 000 | 10 000 | 0,25 |

| 5×30 | 1 000 | 9 000 | 0,28 |

| 5×35 | 1 000 | 8 000 | 0,32 |

| 5×40 | 500 | 7 000 | 0,36 |

| 5×45 | 500 | 6 000 | 0,4 |

| 5×50 | 500 | 5 000 | 0,43 |

| 5×55 | 500 | 5 000 | 0,47 |

| 5×60 | 250 | 4 250 | 0,51 |

| 5×70 | 250 | 3 500 | 0,58 |

| 5×80 | 250 | 3 500 | 0,66 |

| 6×25 | 200 | — | 0,4 |

| 6×30 | 500 | 5 000 | 0,44 |

| 6×35 | 500 | 4 500 | 0,5 |

| 6×40 | 250 | 3 500 | 0,56 |

| 6×45 | 250 | 3 500 | 0,61 |

| 6×50 | 250 | 3 500 | 0,67 |

| 6×55 | 250 | 3 000 | 0,71 |

| 6×60 | 250 | 2 500 | 0,75 |

| 6×70 | 250 | 2 250 | 0,89 |

| 6×80 | 250 | 2 250 | 0,99 |

1.Standard cross stot and in conformity with the PH2 screwdriver bit

2.Phosphate treatment to prevent rust

3.High hardness of sharp thread after heat treatment

4.Sharp tip for screwing in quickly