Factory supply C1022A drywall screw

High quality black fine thread drywall screw manufacturer supply bugle head black gypsum board screw drywall screw that can easily penetrate the steel framing, as well as fine threads that are designed to pass through the steel, also used for plasterboard.Material to be C1022 Steel, finished screws to be further heated/hardend.Surface treatment: black, grey phosphated, zinc or yellow zinc plated.

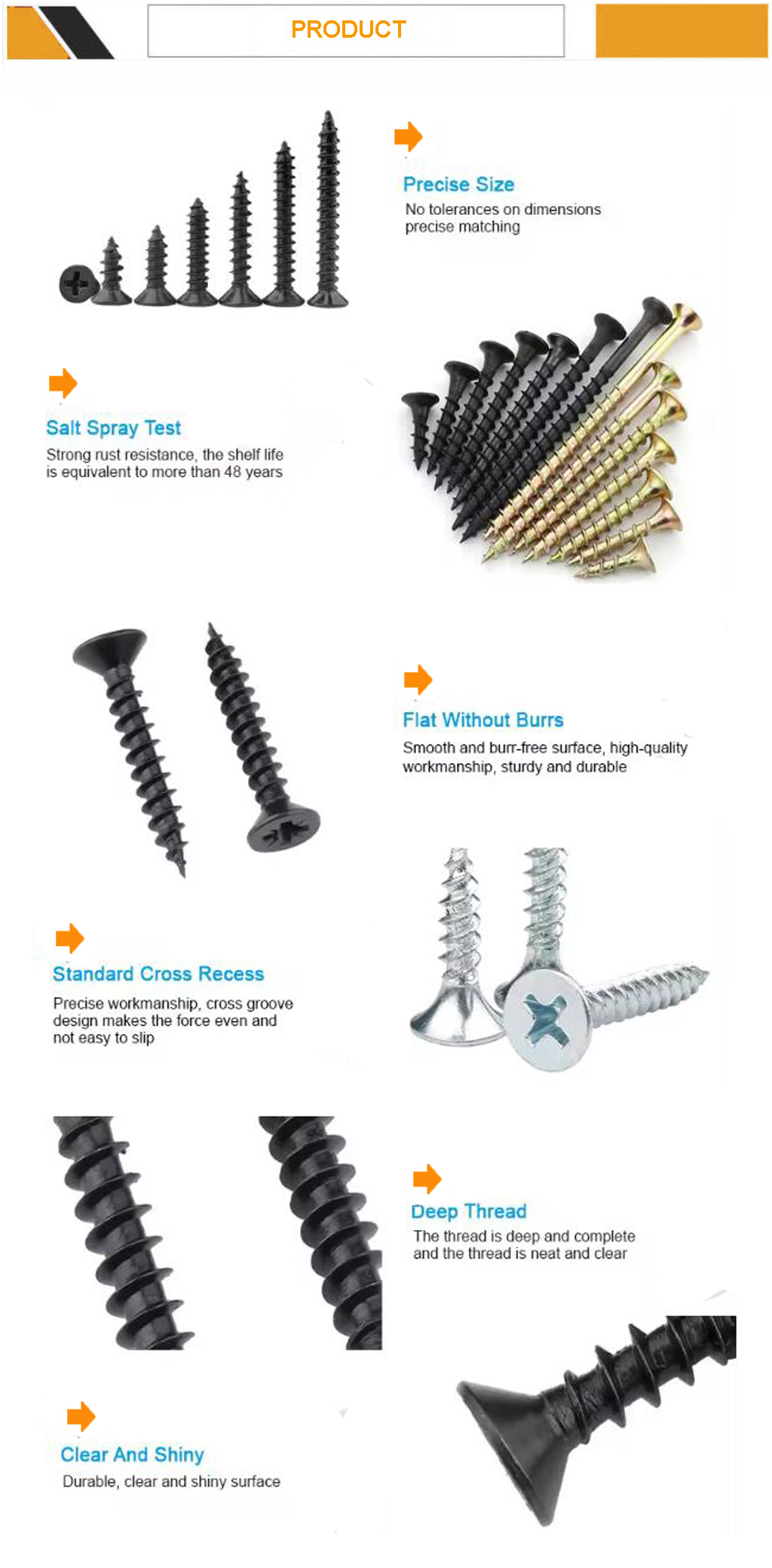

Features:

Made of case hardened steel, the screws offer strong pull strength to hold the drywall.

Sharp points for easy to screw in and damage a little.

Black phosphate coating to increase durability.

Commonly with corrosion coating.

Salt spray test ensures that no color stains the wall.

Speed the drywall installation process.

Long service life.

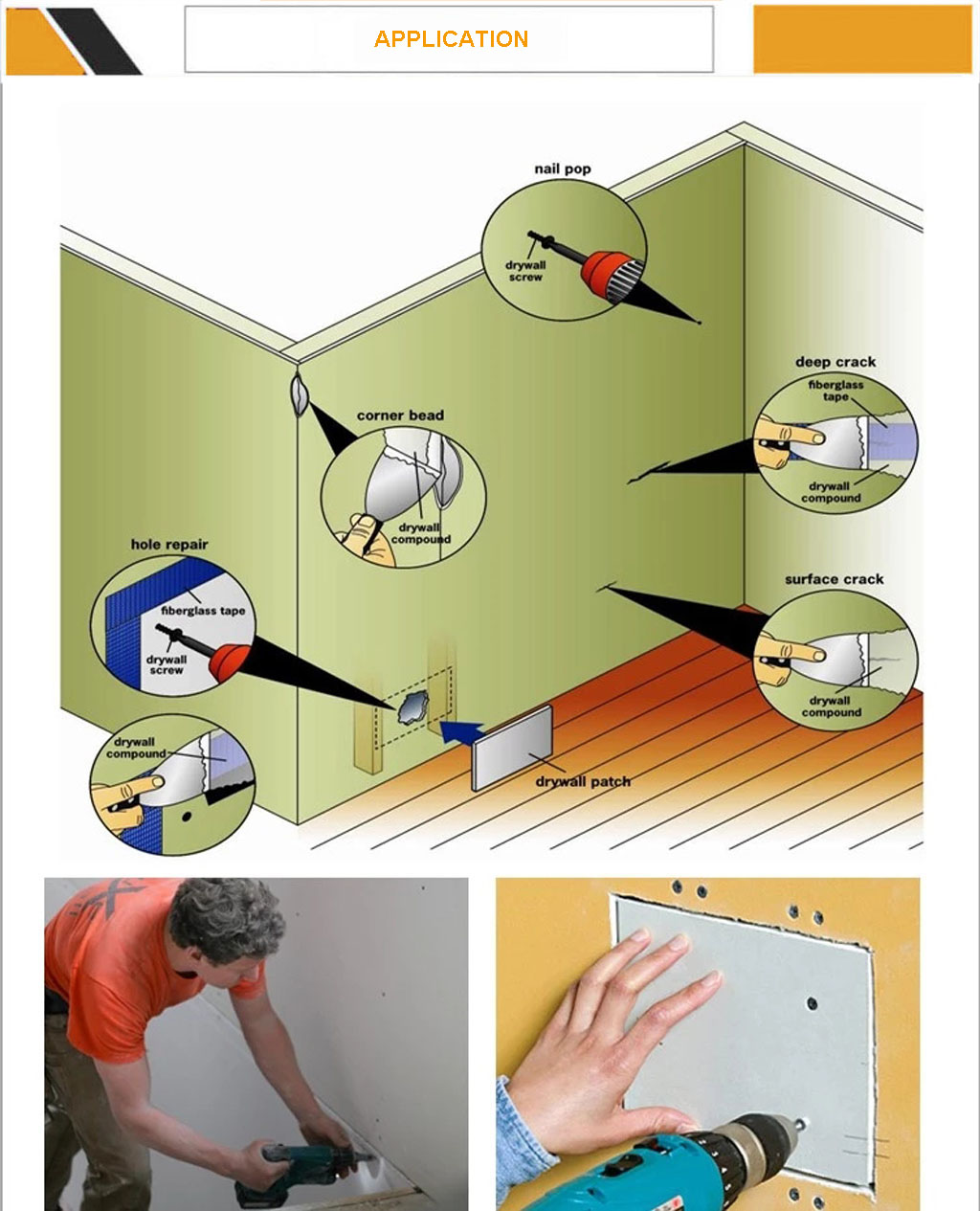

Drywall Screw with Bugle Flat Head Black Phosphate Coarse Fine Thread are used for fastening sheets of drywall to wall studs or ceiling joists. Compared to regular screws, drywall screws have deeper threads. This helps prevent the screws from being dislodged easily from the drywall.Drywall Screw

drywall screws are specifically designed for fastening plasterboard to either metal or timber. Typically, drywall screws are light

and have deeper threads designed to help the screws stay in place against the drywall.

You will probably notice that some drywall screws are silver while others are black – this is down to different coatings.Black drywall screws have a phosphate coating, which protects from rust. Phosphate drywall screws commonly come with a coarse

thread as they’re usually used when screwing drywall into wood, which can suffer more from damp and rust.Silver drywall screws are usually coated in zinc, which also provides corrosion resistance. Generally, these are used for screwing into metal.

| Size(mm) | Size(inch) | Size(mm) | Size(inch) | Size(mm) | Size(inch) | Size(mm) | Size(inch) |

| 3.5*13 | #6*1/2 | 3.5*65 | #6*2-1/2 | 4.2*13 | #8*1/2 | 4.2*102 | #8*4 |

| 3.5*16 | #6*5/8 | 3.5*75 | #6*3 | 4.2*16 | #8*5/8 | 4.8*51 | #10*2 |

| 3.5*19 | #6*3/4 | 3.9*20 | #7*3/4 | 4.2*19 | #8*3/4 | 4.8*65 | #10*2-1/2 |

| 3.5*25 | #6*1 | 3.9*25 | #7*1 | 4.2*25 | #8*1 | 4.8*70 | #10*2-3/4 |

| 3.5*29 | #6*1-1/8 | 3.9*30 | #7*1-1/8 | 4.2*32 | #8*1-1/4 | 4.8*75 | #10*3 |

| 3.5*32 | #6*1-1/4 | 3.9*32 | #7*1-1/4 | 4.2*34 | #8*1-1/2 | 4.8*90 | #10*3-1/2 |

| 3.5*35 | #6*1-3/8 | 3.9*35 | #7*1-1/2 | 4.2*38 | #8*1-5/8 | 4.8*100 | #10*4 |

| 3.5*38 | #6*1-1/2 | 3.9*38 | #7*1-5/8 | 4.2*40 | #8*1-3/4 | 4.8*115 | #10*4-1/2 |

| 3.5*41 | #6*1-5/8 | 3.9*40 | #7*1-3/4 | 4.2*51 | #8*2 | 4.8*120 | #10*4-3/4 |

| 3.5*45 | #6*1-3/4 | 3.9*45 | #7*1-7/8 | 4.2*65 | #8*2-1/2 | 4.8*125 | #10*5 |

| 3.5*51 | #6*2 | 3.9*51 | #7*2 | 4.2*70 | #8*2-3/4 | 4.8*127 | #10*5-1/8 |

| 3.5*55 | #6*2-1/8 | 3.9*55 | #7*2-1/8 | 4.2*75 | #8*3 | 4.8*150 | #10*6 |

| 3.5*57 | #6*2-1/4 | 3.9*65 | #7*2-1/2 | 4.2*90 | #8*3-1/2 | 4.8*152 | #10*6-1/8 |