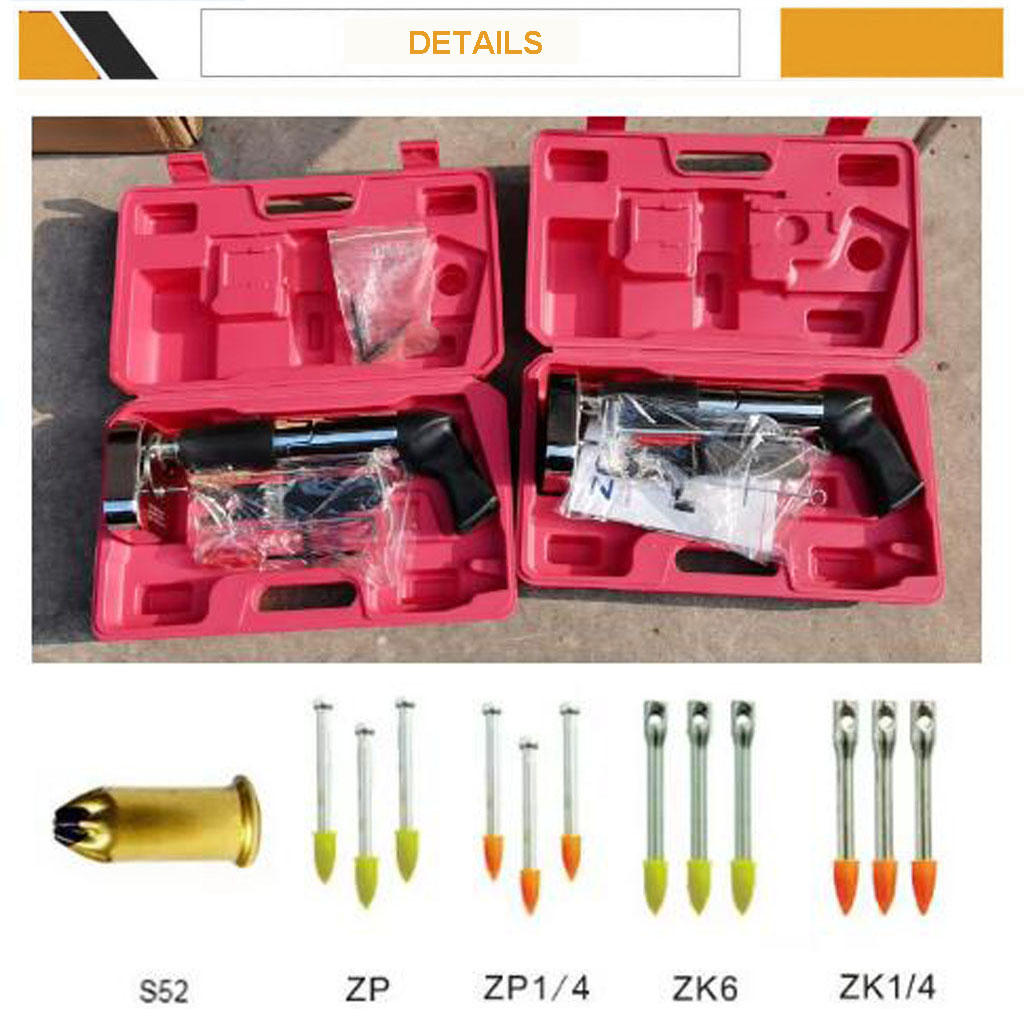

ZP & ZK SERIES DRIVE PIN

BRIGHTWAY drive pins use good quality high carbon steel as raw mateiral which meets International strandard (AISI 1060-1065) to ensure the products’ quality in high position.

BRIGHTWAY drive pins adopted advanced manufacturing process so as to attain the international highest standards for fasteners:

—- Austempered to a core hardness of 55-58 HRC

—- Typical Tensile strength more than 270,000 psi

—- Typical Shear Strength more than 162,000 psi

1.Forged with carbon steel,high strength,no deformation,strong penetrating ability

2.The surface is glossy andround,not easy to rust,quality and beauty coexist

3.The cone point is sharp,strong penetrating power,and can be inserted as soon as it is penetrated, which greatly saves installation time.Each piece is protected by an indep en dent cap

4.Waterproof and moisture-proof,Durable,Better material

SHOOT NAILS WITH POINT EYE DRIVE PINS In this system, power actuated tool strikes power load,ignited power load drives SHOOT NAILS into steel, concrete,brick and rock to fasten elements such

as conduits, steel parts,doors, windows, boards, ceiling and other ornaments etc temporarily or permanently.

Application

Powder actuated fastening on steel, concrete and sand-lime block

For driving pins, studs, etc. into concrete and steel

The charges are activated when a firing pin strikes the primer, which is an explosive charge in the base of cartridge. The primer ignites the charge, which burns rapidly. The gases released by the burning of the propellant build pressure within the cartridge, which acts either on the head of the nail, or on the piston, accelerating the nail towards the muzzle.