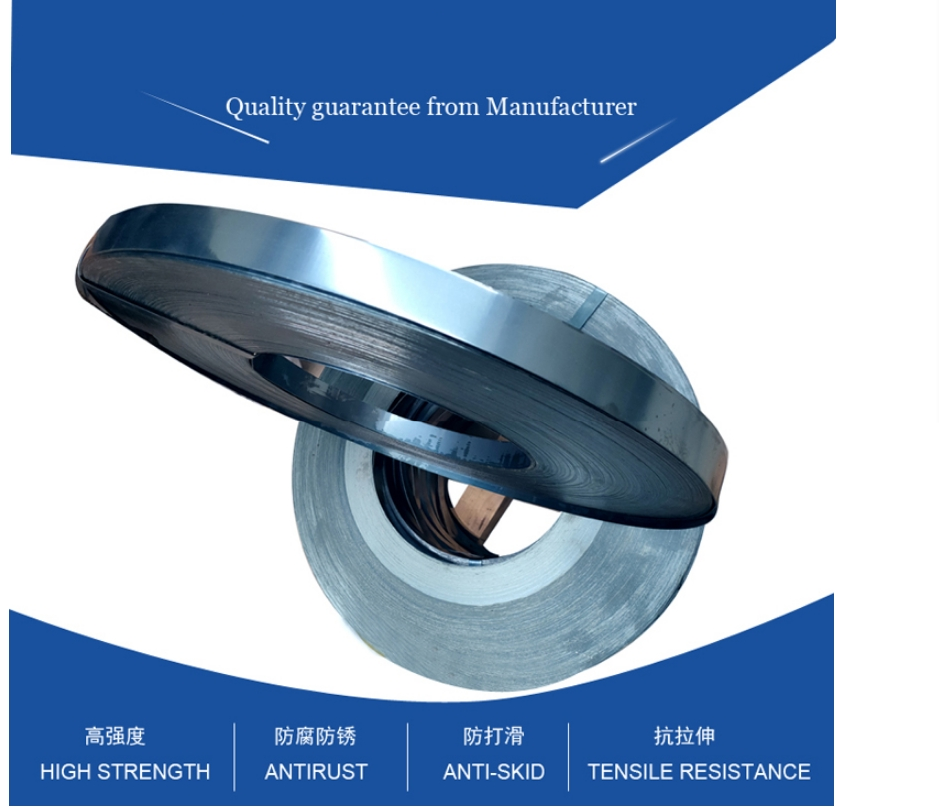

M-S BINDING STRIP

1.65Mn The steel is a commonly used spring steel. It has high strength, poor hardenability, low decarbonization tendency, low price and good machinability. But there is overheating sensitivity, easy to produce quenching crack, and temper brittleness. It is widely used for making various flat and round springs, plate springs and spring sheets with small cross sections

2.70# steel has high strength, but low hardenability, suitable for manufacturing springs with small cross section (φ≤15mm). Cold work hardening steel wire, in the cold state of winding forming, only for low temperature tempering, eliminate stress. The steel has good machinical-bility and large quenching deformation. It is mainly used for non-quenched small spiral spring, spring sheet, elastic washer, stop ring, etc.

3.T9A The steel is high quality carbon tool steel and spring steel. After quenching and tempering, it has high hardness and toughness, poor hardenability, large quenching deformation and low plasticity. It is often used to manufacture tools and springs with high hardness and free from violent shock.

4.60Si2MnA it is a very widely used alloy spring steel. The steel hardenability is good. It has high strength and elastic limit after quenching and tempering. Higher compressive strength ratio (б0.2/б B), anti-relaxation ability and tempering stability. If is other mal quenching is needed, its comprehensive performance is better. In particular, the fatigue life is improved obviously, but the decarbonization tendency of the steel is large, and the cold deformation plasticity is low. The cutting is heavy. The thickness is less than 10mm for work below 250℃. Diameter & lt; 25 mm all kinds of spring, spiral spring, safety valve spring,damping spring, instrument spring, etc

5.50CrVA steel is a high quality spring steel. With high proportional limit and strength, high fatigue and good plasticity and toughness, good tempering stability, when heated to 300℃ elasticity can still be maintained. The steel machinability is good. But the plasticity of cold working is poor. Poor weldability. Suitable for the manufacture of all kinds of important springs under high stress, the operating temperature does not exceed 400℃.