PE Polyester Industrial Non-woven Dust Filter Media Needle Felt Dust Fabric Cloth for Cement Plant Dust Filter Bags

Pre filter Media is also know as nonwoven filter media. Nonwovens are typically manufactured by putting

small fibers together in the form of a sheet or web (similar to paper on a paper machine), and then binding

them either mechanically(as in the case of felt, by interlocking them with serrated needles such that the

inter-fiber friction results in a stronger fabric)with an adhesive, or thermally (by applying binder (in the form

of powder, paste, or polymer melt) and melting the binder onto the web by increasing temperature).

ADVANTAGES

1. High Efficiency/Perfomance

2. Disposibility/Recyclability

3. Pleatability/Moldablity/

4. Durability, Sustainability,Longer Life

5. Anti-bacterial

6. "Green" Impact in Production, Energy Saving

Applications of Textile industry polypropylene liquid filter bag for filtration :

1.Paints & lacquer industry

2.Wastewater treatment

3.Pharmaceutical industry

4.Food industry

5.Chemical industry

6.Beer, wine & spirit industry

SFF supply Textile industry polypropylene liquid filter bag for filtration

Polyester Filter bag is mainly used for industrial dust collection, clean air and protecting the environment.

Polyester Filter advantages:

1. Good Temperature-Resistance. Max. Temp. 150°C

Physical Stability , Good Abrasion-Resistance.

2. High Filtration Efficiency: reach to 99.5%

3. Stable working time: up to more than 3000 hours. Could be used cyclically.

4. Variety of finish treatments.

5. Competitive Price with Good Quality.

6. Various Applications: Cement plant,Steel and iron industry,Flour Industry, Chemical industry etc.

7. Customized by order.

PE Physical Properties:

Weight(gsm)

|

500

|

|

Thickness(mm)

|

1.7

|

|

Width(mm)

|

≤2.2m

|

|

Finish treatment

|

Singeing, Calendering, Heat setting

|

|

Air permeability(L/m2.s)

|

200-300

|

|

Tensile strength(N/5cm)

|

warp

|

≥1100

|

weft

|

≥1500

|

|

Tensile elongation(%)

|

warp

|

≤35

|

weft

|

≤60

|

|

Heat shrinkage(%)

|

warp

|

≤1.5

|

weft

|

≤1.0

|

|

Temperature(°C)

|

Continue

|

130

|

Instant

|

150

|

|

PE Chemical Properties:

Anti-acid

|

Middle

|

Anti-alkali

|

Middle

|

Anti-abrasion

|

Excellent

|

hydrolysis stability

|

Middle

|

Product features: 1,Higher adsorption capacity and faster adsorption velocity 2,Easy regeneration and faster desorption velocity 3,Best heat regeneratioin and lowest ash content 4,Acid-resisting,alkali-resisting,there is better electric conductivity and chemical stability. 5,Easy to profile of activated carbon fiber can be made into different shape, like felt, silk, cloth and paper etc.

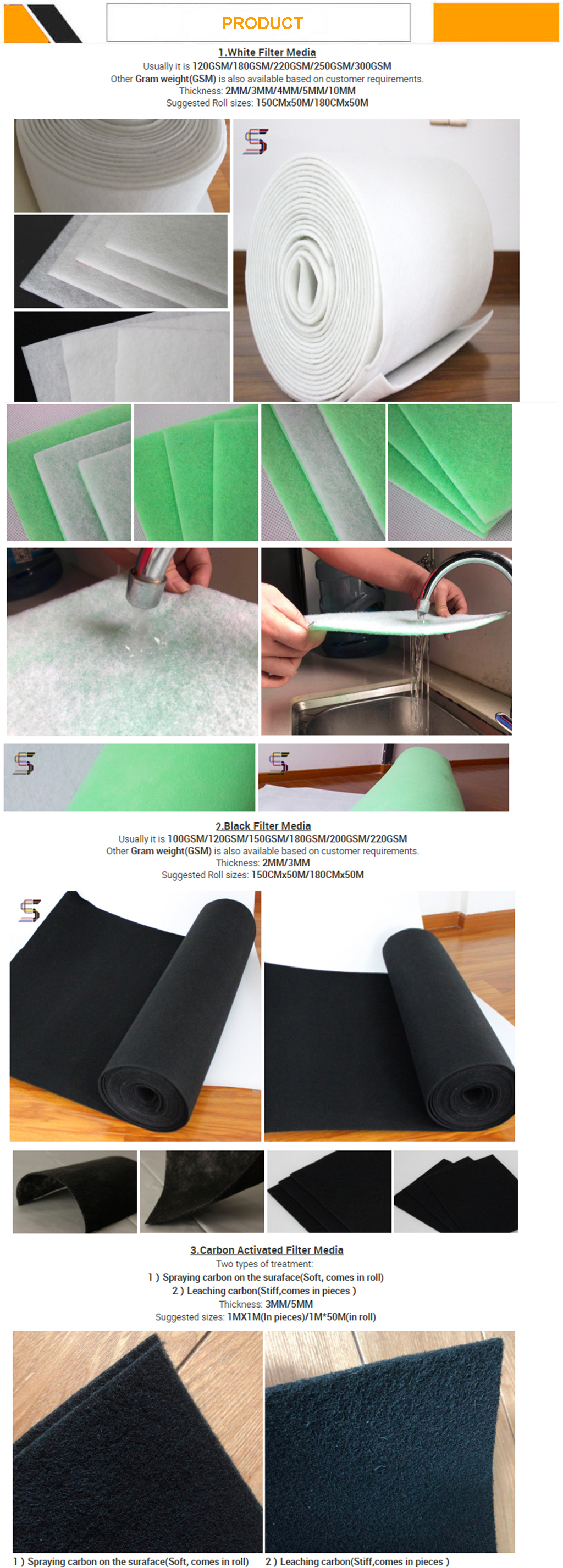

1.white filter media

usually it is 120GSM/180GSM/220GSM/250GSM/300GSM

other gram weight(GSM) is also avaialbe based on customer requirements.

Tickness:2MM/3MM/4MM/5MM/10MM

Suggested roll sizes:150cm*50m/180cm*50m

2. black filter media

usually it is 100GSM/120GSM/150GSM/180GSM/200GSM/220GSM

other gram weight(GSM) is also avaialbe based on customer requirements.

Tickness:2MM/3MM

Suggested roll sizes::150cm*50m/180cm*50m

3.carbon activated filter media

two types of treatment

1)spraying carbon on the suraface (soft comes in roll)

2)leaching carbon(stiff comes in pieces

Tickness:3MM/5MSuested sizes:*1M(IN PIECES)/1M*50M(in roll).