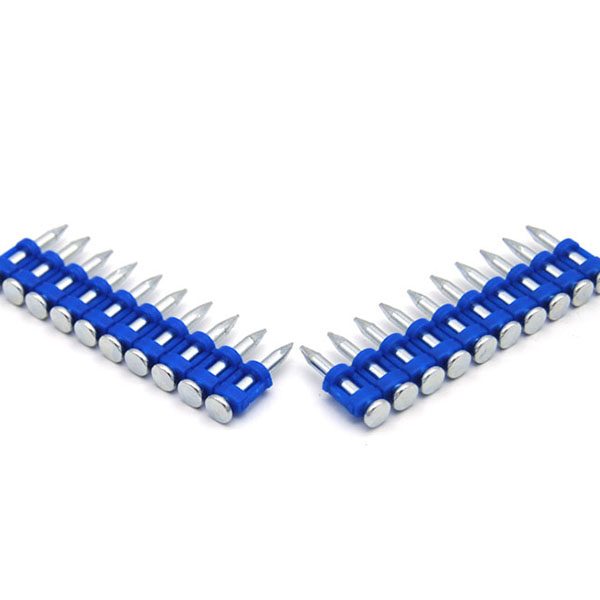

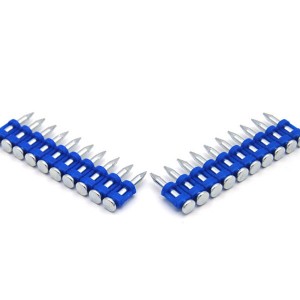

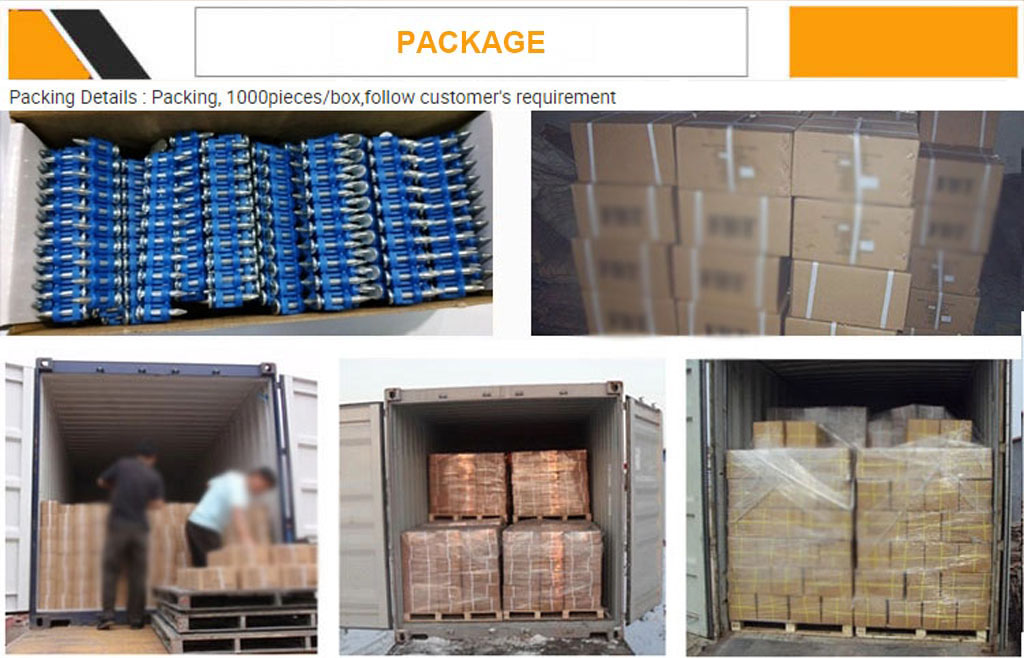

DOWN SHANK GAS PIN 38mm For RAMSET

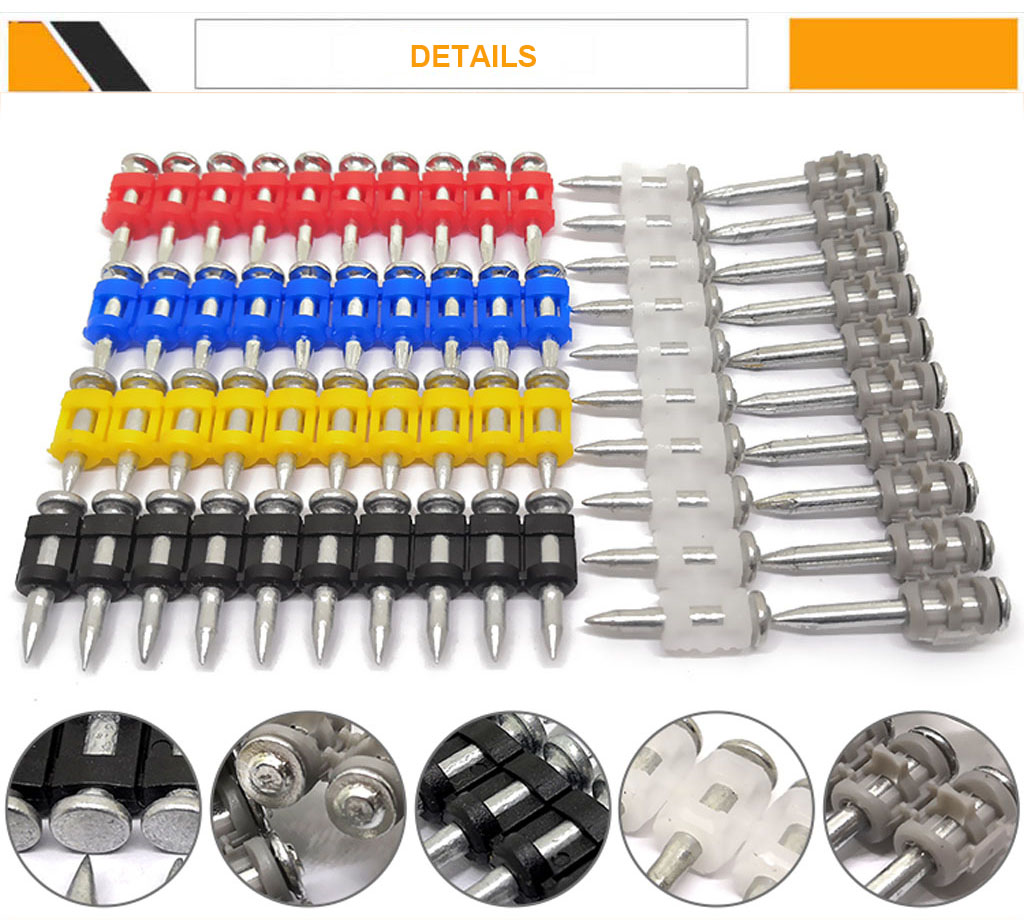

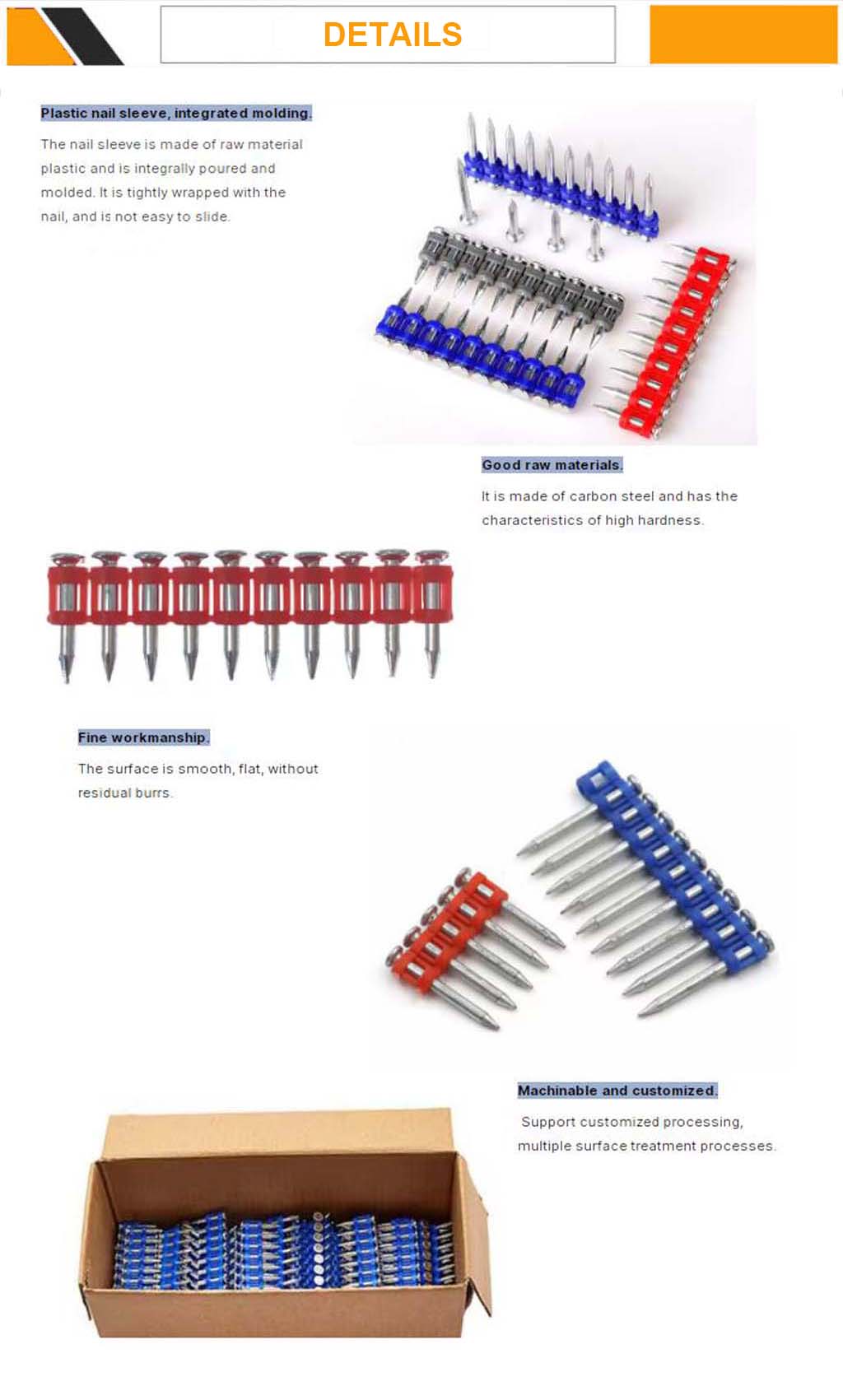

Gas pin nails are gunpowder gas generated from launch blank as power, into the building of the nail. Usually by a nail and gearring or plastic positioning of retainer ring.Gear ring and plastic positioning the role of the retainer ring is fixed on nail nail body publish or perish tube, in order to prevent fires cornering. Is the role of nail nail into the concrete.

Nail gun for nail fastening technology is an advanced modern fastening technology, with the traditional fixed, embedded hole pouring, bolt connection, welding compared with the method, it has many advantages: bring energy, so as to get rid of the wire and duct drag, facilitate the scene and aerial work;Rapid operation, short time limit, can greatly reduce labor intensity;Function is reliable and safe, can even solve some construction problems difficult to solve in the past; Save money, reduce construction cost.The principle of a gas gun: The pneumatic nail gun includes a gun body and a pneumatic valve control mechanism. The pneumatic valve control mechanism is provided with a pneumatic valve chamber and a manual valve chamber respectively on the cylinder side of the gun body, and the two valve chambers are combined with each other to form a control air path. The pneumatic valve chamber is provided with a balance valve, and the balance valve is covered with a valve sleeve. The bottom of the nozzle in the manual valve chamber passes through the manual valve chamber and corresponds to the plate handle. At each pressure, a certain amount of gas gas is ejected quantitatively from the top of the gas tank into the combustion chamber (cylinder) inside the gun body, and the trigger is triggered by the electronic spark ignition to make the gas erupt, thus generating a driving force to push the needle forward and complete the nail work. The core principle of this tool is similar to that of a car engine and requires regular maintenance. Good cleaning and maintenance can greatly improve the service life and nailing force of tools. After each cleaning need to apply appropriate amount of special lubricating oil in the piston ring and cylinder wall. Brand of gas gun: toua gas gun is suitable for the installation of doors and Windows, water and electricity, steel plate, monitoring, concrete and other walls. Compared with the traditional nail installation method, this improves installation efficiency and saves labor costs. Industrial grade design, suitable for high strength use, can make the operator reduce fatigue and work faster, very practical.