Factory cheap price galvanized common nail factory

Iron nails, having a flat head at one end and a sharp end at the other, are used mainly for fixing or connecting. In the early days, because China’s technology was backward, iron nails once relied on imports, for “imported goods”, so the iron nails are called “foreign nails”. There are many kinds of nails, commonly used are ordinary nails, felt nails, cement steel nails, headless nails, shooting nails, roll nails. The surface is galvanized, copper plated, etc., according to actual needs to choose.

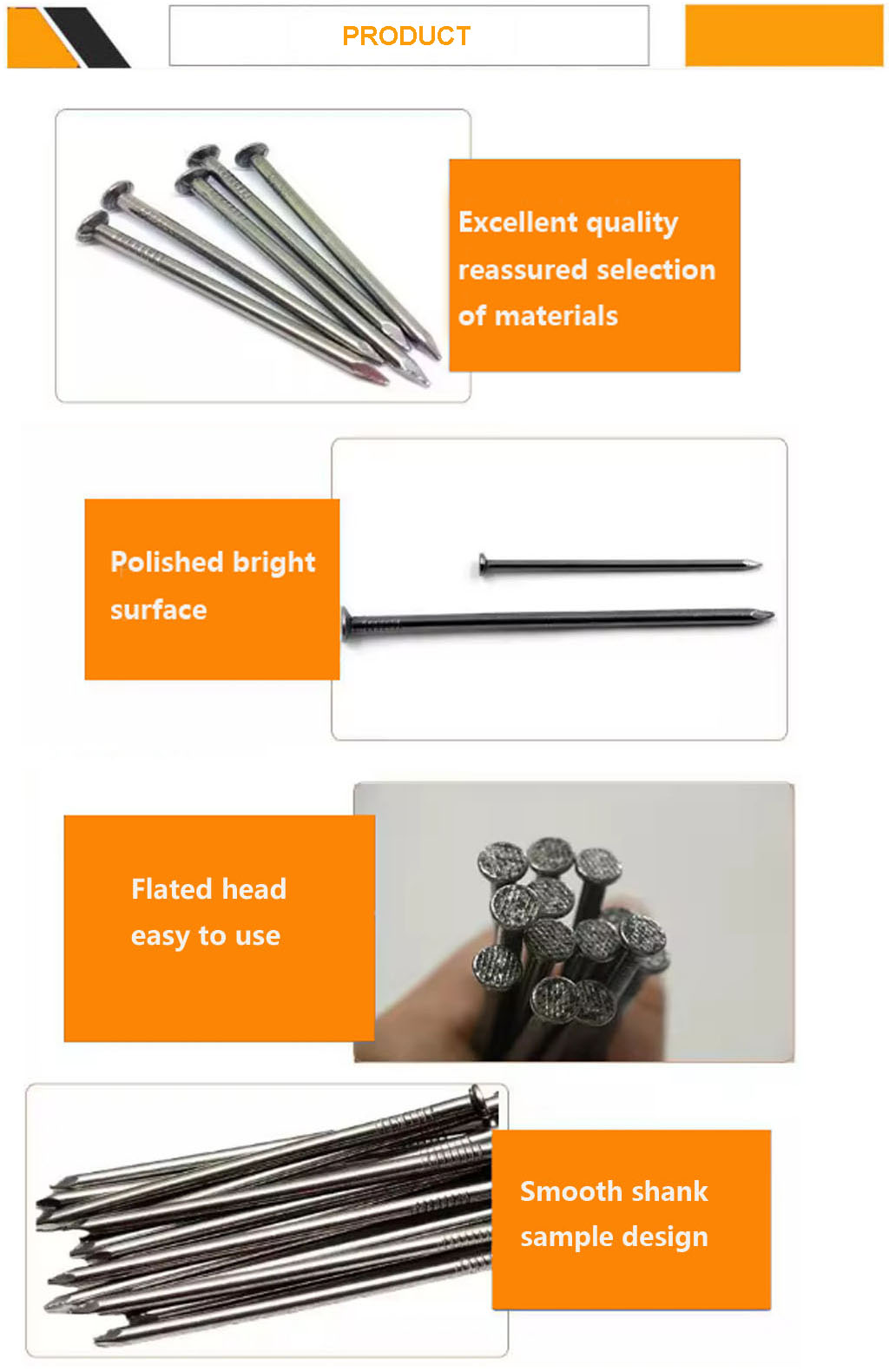

Features :

Common nails are strong and stiff, and their shanks have greater diameters than other nails. Both common and box nails have

notches near the head of the nail. These notches allow the nails to hold better. Some will have screw-like threads at the top of

the nail head for extra holding power. Box nails have thinner shanks than common nails and shouldn’t be used for framing construction. When nailing two boards together, both types of nails should completely penetrate one piece of wood and should penetrate the other piece with half its length. This ensures the nail is strong enough for the job.

| Length | Gauge | |

| (Inches) | (MM) | (B.W.G) |

| 1/2 | 12.700 | 20/19/18 |

| 5/8 | 15.875 | 19/18/17 |

| 3/4 | 19.050 | 19/18/17 |

| 7/8 | 22.225 | 18/17 |

| 1 | 25.400 | 17/16/15/14 |

| 1-1/4 | 31.749 | 16/15/14 |

| 1-1/2 | 38.099 | 15/14/13 |

| 1-3/4 | 44.440 | 14/13 |

| 2 | 50.800 | 14/13/12/11/10 |

| 2-1/2 | 63.499 | 13/12/11/10 |

| 3 | 76.200 | 12/11/10/9/8 |

| 3-1/2 | 88.900 | 11/10/9/8/7 |

| 4 | 101.600 | 9/8/7/6/5 |

| 4-1/2 | 114.300 | 7/6/5 |

| 5 | 127.000 | 6/5/4 |

| 6 | 152.400 | 6/5/4 |

| 7 | 177.800 | 5/4 |