Galvanized collated drywall screw collated self-tapping screws

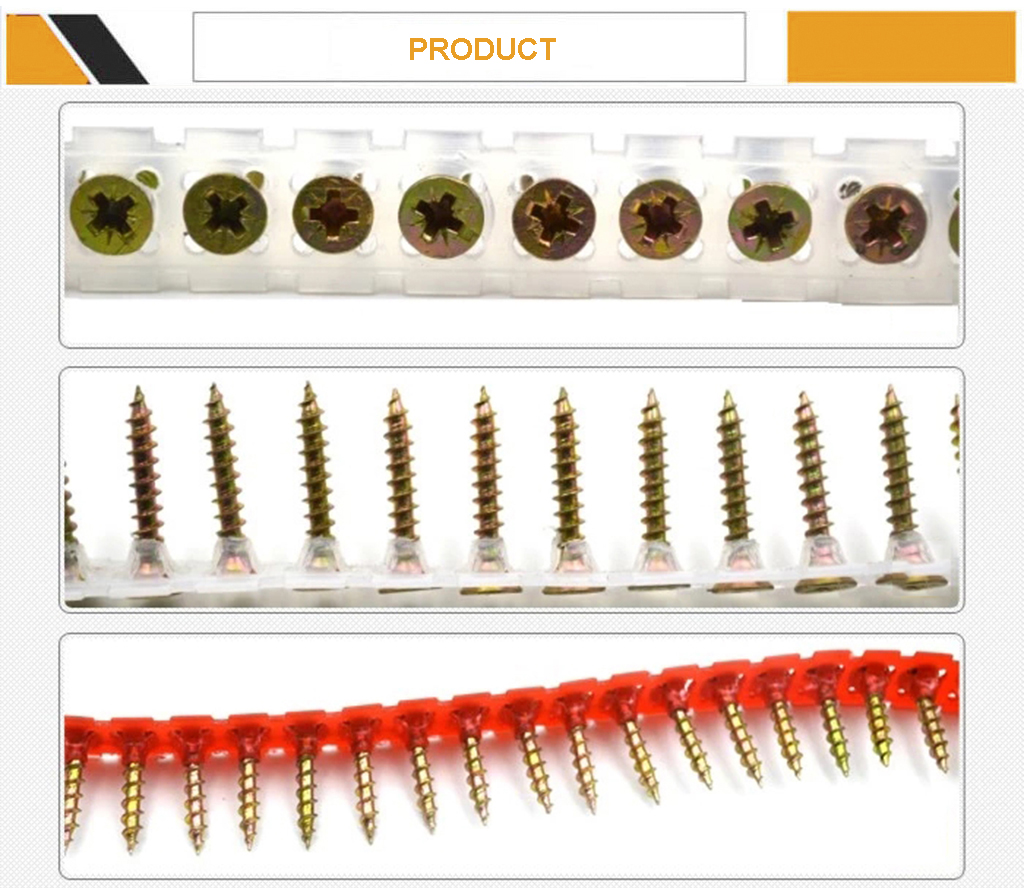

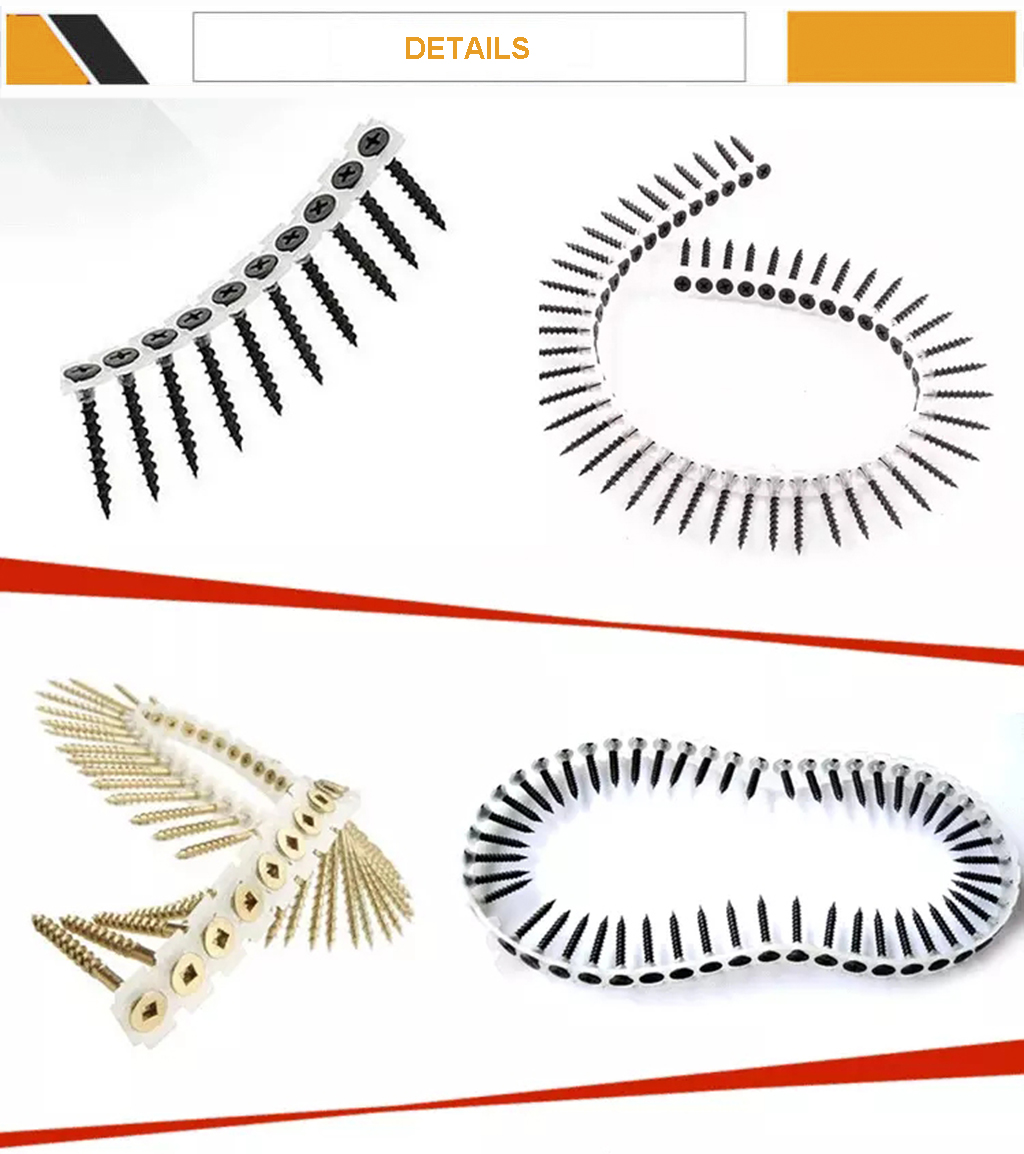

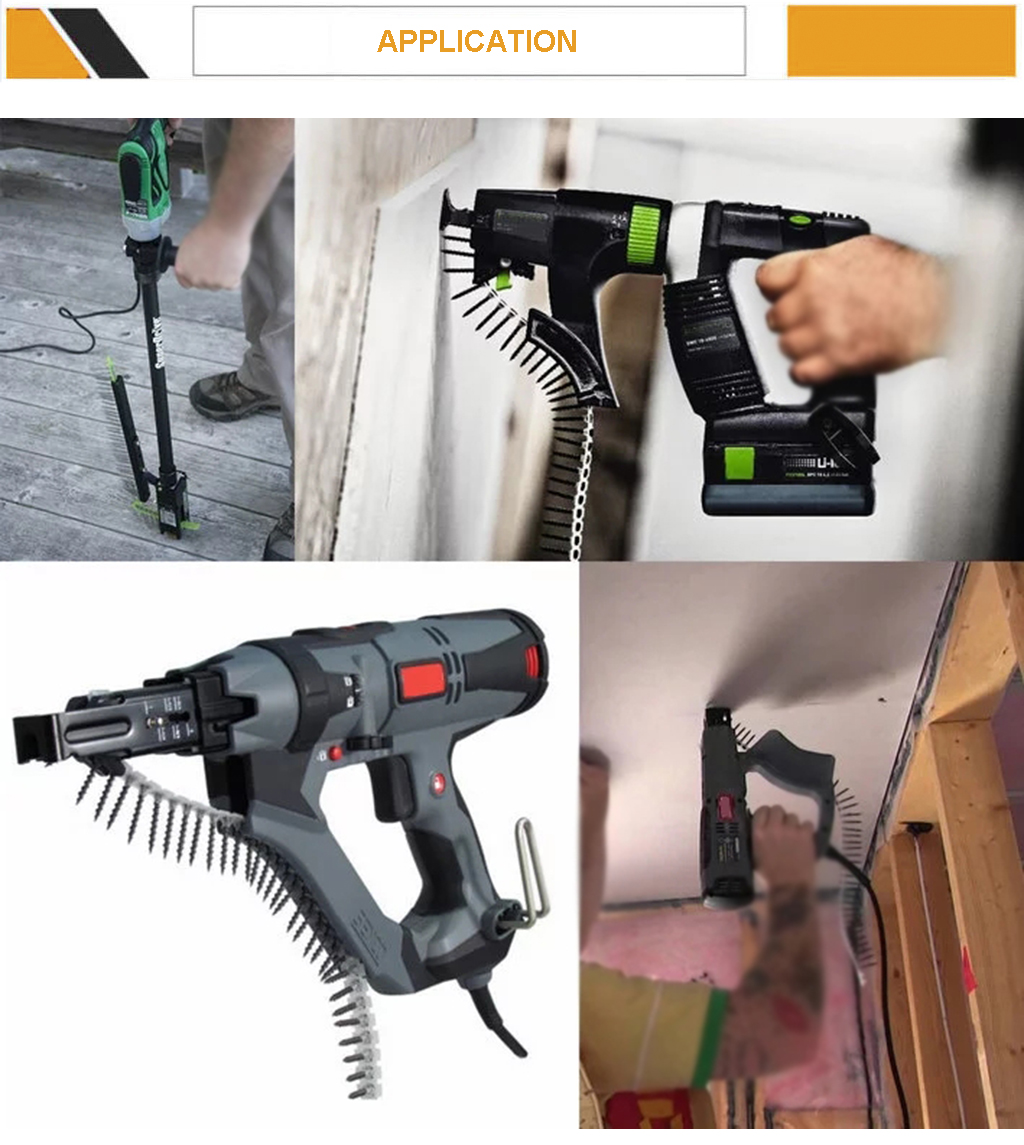

Collated screws are screws that are held together with a durable plastic strip designed to fit perfectly into all leading brand auto-feed screw-guns. The collating process is fully automated to ensure that the screws and plastic strip are mated perfectly toprevent jamming in the auto feeder system. The most common collated screw types are bugle head drywall screws. Bugle head drywall screws are used to secure drywall sheets to ceiling joists, wall studs, wood, metal tracks and more.

Collated drywall screws mean increased productivity. Like their nail and staple counterparts, Collated screws offer professional installers a number of benefits, not the least of which is an overall increase in job productivity. This is due in part to the fact that collated systems reduce the amount of time spent loading and installing loose fasteners, eliminating the need for feeding one fastener at a time.

Black phosphate coating for increased corrosion resistance. Phillips drive, bugle head and sharp point allows fast penetration through studding or batons without surface damage to board.Features

* Material: Made of carbon steel C1022A to make the Drywall Screw have stronger strength. Adopt high-strength rolling arm, small gap, mute, wear-resistant, uniform force.

* Bugle head: It is the most obvious character of the Drywall Screws. Most of the Drywall Screw’s head are in this shape. So Drywall Screws are called “bugle screws”or “Phillips bugle head screws” as well refer to the shape of the screw’s head. It helps the screw stay in place without tearing all the way through the outer paper layer. The Phillips groove helps not slip when use the screw gun.

* Groove: Most of the Drywall Screws use the Phillips groove. The cross groove does not slip.

* Sharp Point: Some of the Drywall Screws with sharp point which make them easier to stab the screw into drywall. Some of the Drywall Screws with drill point which make them have stronger strength.

* Drill Point: Drywall Screw with drilling point is also called tek screw, which could be used in sheet metal fixing or other hard material fixing.

* Surface Treatment: After a phosphate coating and heat treated to make the Drywall Screws resist corrosion and harder.

* Coarse Thread: It is known as W-type Screws. They are work best for fastening gypsum to wood studs. The wide and deeper threads mesh with the wood grain and provide more gripping area than fine thread Drywall screws. Since there are wider threads on the coarse thread sharp screws, it is more easily cut fingers when use them, so it is best to wear gloves when working with coarse thread wood screws, plasterboard screws and drywall screws.

* Fine Thread: It is known as S-type screws. Their threads are closer than the Coarse thread. They are used primarily when attaching gypsum to metal studs. The sharp threads surrounding the screw mean less surface area to grip metal. Are able to efficiently cut their own secure path into the metal material, which is much harder than wood grain. So the Fine threaded screws are work well with metal because they have sharp points and are self-threading.

* Our Advantage: Adopt high-speed cold heading machine to form one piece, high strength. Self-owned heating treatment producing line, which can promise screws hardness and strength well perform always.Stable drilling speed, not easy to break.