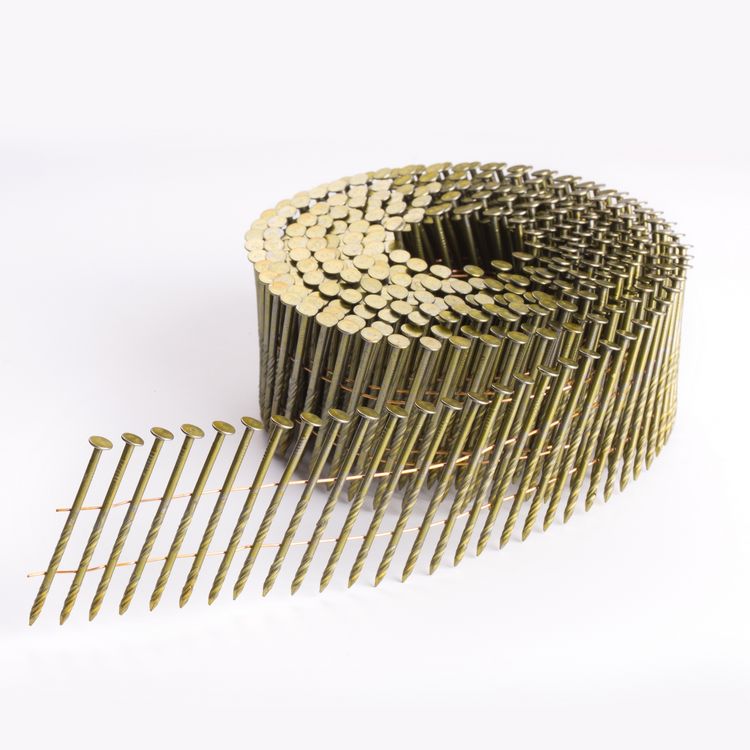

Diamond Point Ring Shank Coil Roofing Nail For Pallet Nails From China

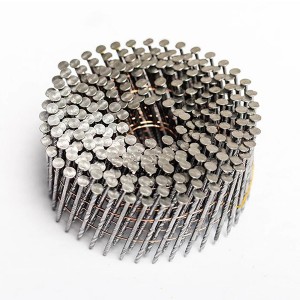

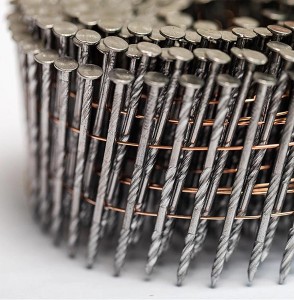

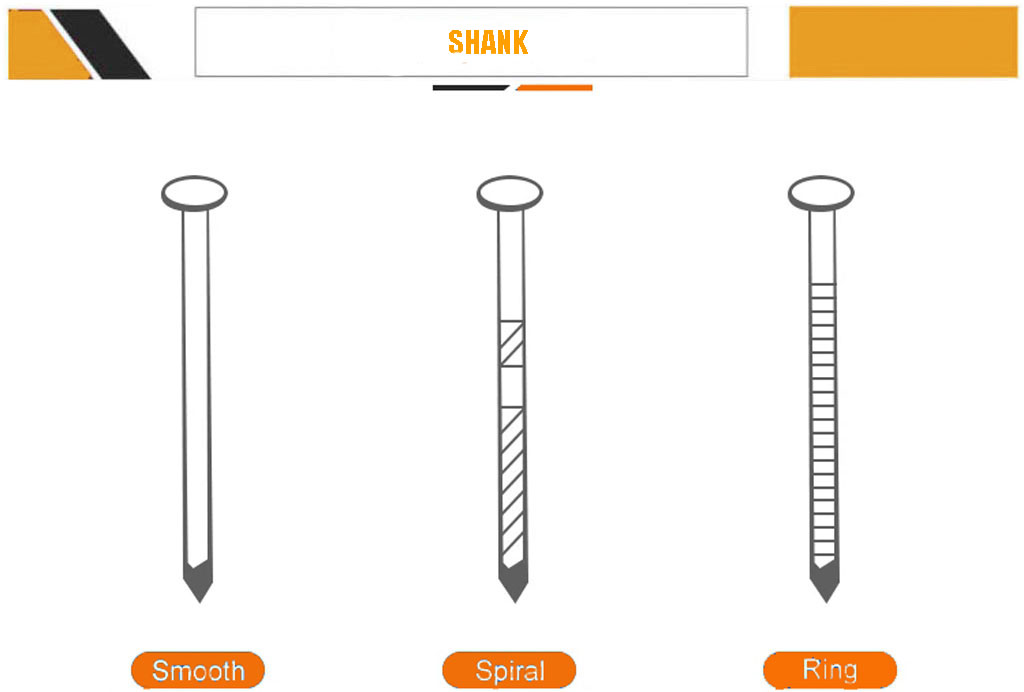

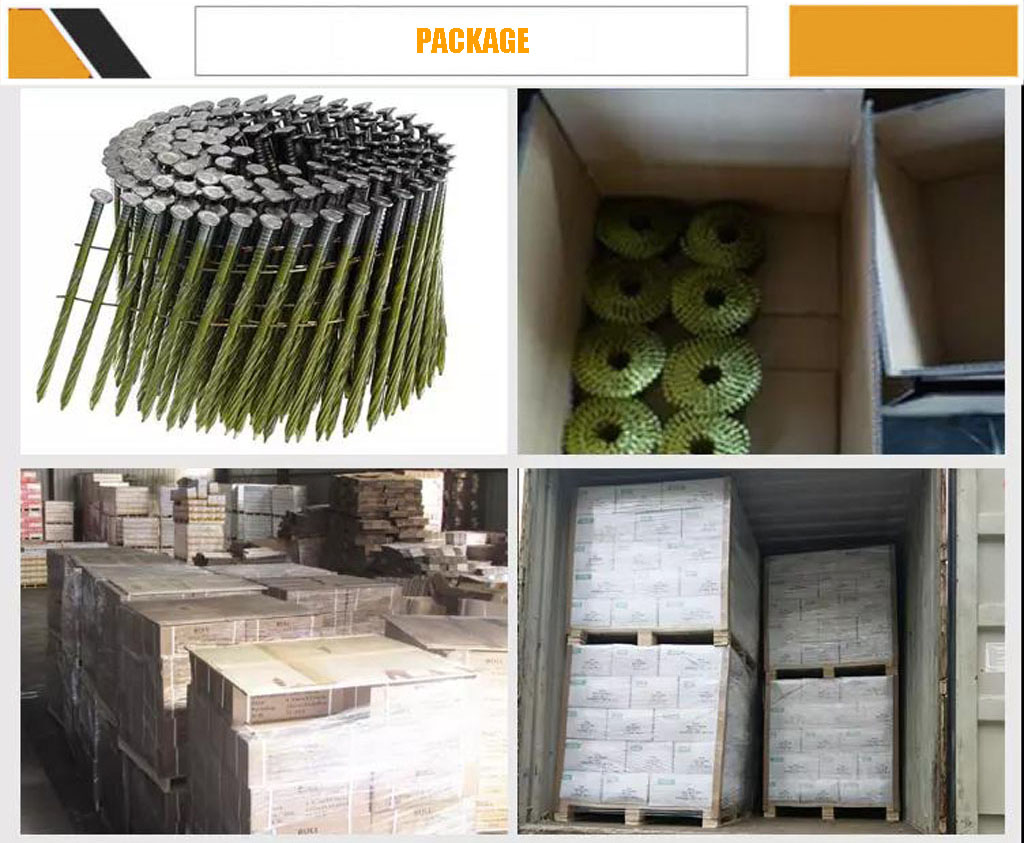

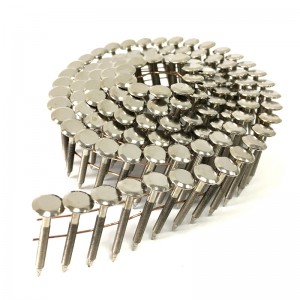

Coiled nails refer to nails which are assembled together in coils by steel wires, hence the name wire collated nails. Main types.include coiled smooth shank nails, coiled ring shank nails and coiled screw nails. These wire-collated coiled nails are compatible with pneumatic wire coil framing nailers. As a reliable manufacturer, we own advanced manufacturing processes for accurate collation. So as to ensure proper feeding of fasteners and less down time. In this way, SSS workers can do their jobs more efficiently and perfectly. Main application fields include binding of pallet & crate, fencing, garden furniture and external cladding fixation, etc.

Coil welded nails are used in various industries. The assembly of #pallets, #furniture, #building construction, boats and all types of fastening that require high production speed. Largely increases the nailing speed due to the efficiency of pneumatic nailers that replace common hammers.

| Item | Diameter(mm) | Length(mm) | Head Diameter(mm) |

| COIL NAIL | 2.05-2.15 | 25-27 | 4.8-5.0 |

| 2.05-2.15 | 32-40 | 4.8-5.0 | |

| 2.05-2.15 | 45-55 | 4.8-5.0 | |

| 2.20-2.30 | 38-45 | 5.5-5.7 | |

| 2.20-2.30 | 50-55 | 5.5-5.7 | |

| 2.35-2.45 | 40-50 | 6.3-6.5 | |

| 2.35-2.45 | 55-60 | 6.3-6.5 | |

| 2.35-2.45 | 63-70 | 6.3-6.5 | |

| 2.65-2.95 | 57-65 | 6.5-6.8 | |

| 2.75-3.10 | 70-90 | 6.5-6 |

Send your message to us:

Write your message here and send it to us