Black Annealed Wire Building Material Iron Twisted Soft Annealed Black Iron Binding Wire

Black wire offers excellent flexibility and softness through the process of oxygen free annealing. And the black oiled wire is formed via the process of wire-drawing, anneal, and fuel oil injection. We can do according to customers’ special requirement. Binding wires are made of galvanized, plastic coated annealed and stainless steel wire. It is softness, good ductility and high strength, and is easily bent and tied in a knot. Binding wire with heat treatment will have high strength and become softer. Cover the wire with zinc, its resistance to corrosion will be strength. Galvanized binding wire has a matte or shiny finish, and it is easy to oppose the negative effects of the environment. PVC coated binding wire has resistance to corrosion.

Advantage:

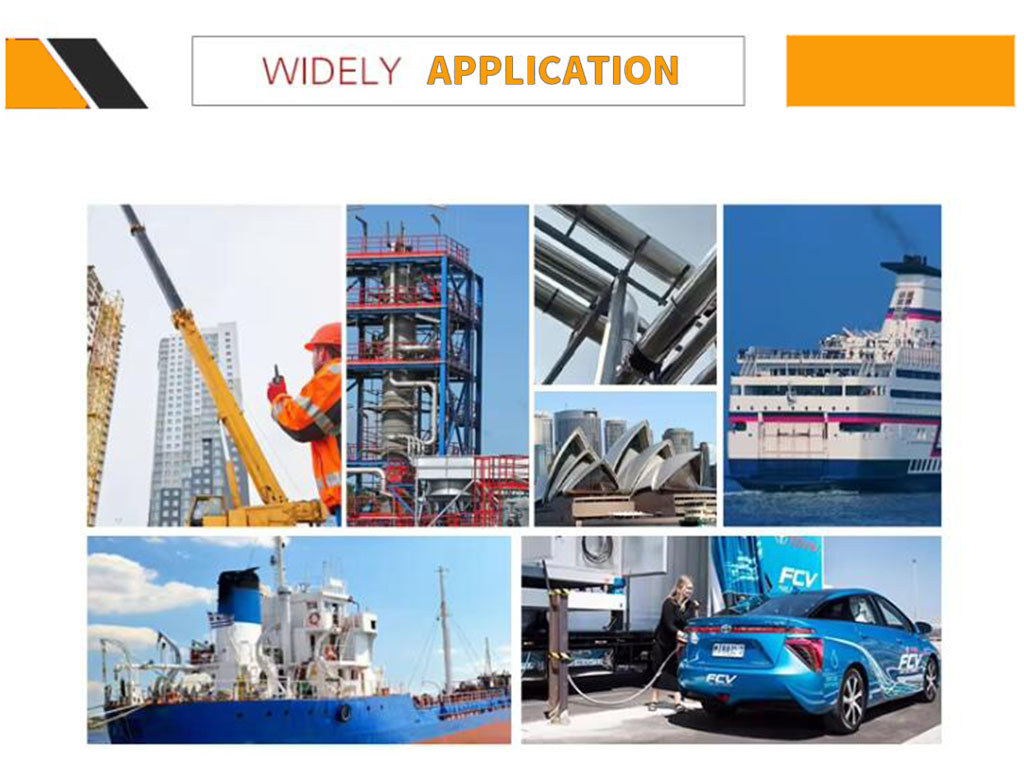

Black wire is a versatile wire that can be used in many industries and applications. Black wire is considered a hot wire, meaning it carries a live current from the electrical panel to its destination. Black wires are generally used to transfer power to switches and outlets in circuits. Black steel wire is an annealed wire that is malleable and resilient. Annealing is a heat treatment that changes the physical and chemical properties producing a soft.

|

Wire Gauge |

SWG in mm |

BWG in mm |

In Metric System mm |

|

8# |

4.06 |

4.19 |

4.00 |

|

9# |

3.66 |

3.76 |

- |

|

10# |

3.25 |

3.40 |

3.50 |

|

11# |

2.95 |

3.05 |

3.00 |

|

12# |

2.64 |

2.77 |

2.80 |

|

13# |

2.34 |

2.41 |

2.50 |

|

14# |

2.03 |

2.11 |

- |

|

15# |

1.83 |

1.83 |

1.80 |

|

16# |

1.63 |

1.65 |

1.65 |

|

17# |

1.42 |

1.47 |

1.40 |

|

18# |

1.22 |

1.25 |

1.20 |

|

19# |

1.02 |

1.07 |

1.00 |

|

20# |

0.91 |

0.89 |

0.90 |

|

21# |

0.81 |

0.813 |

0.80 |

|

22# |

0.71 |

0.711 |

0.70 |

Send your message to us:

Write your message here and send it to us